About Transglutaminase (TG)

Transglutaminase (TG) is an enzyme which is widely distributed in nature, and is composed of simple amino acid chains, and has been studied by many researchers for food use around the world. Siveele Transgluseen product is produced through fermentation process which is similar to making beer, wine and cheese, using conventional microorganisms.

TG preparation is able to improve the physical properties of various foods containing proteins. The use of the product offers various benefits to food companies and final consumers. In bakery and milk products, TG preparation improves texture. In process meat products, such as emulsified sausage and cooked ham, it improves texture and increases connectivity, thus decreasing loss during manufacturing process. In meat and fish, TG preparation enables combining quality parts of meat/fish, decreasing loss and waste, and consequently reducing pricing of the final products. This is an important contribution to a responsible and sustainable food chain. This also helps to reduce the negative environmental effects of farming by maximizing the use of the food that is produced. TG preparation also replaces binding agents such as salt, allowing consumers to benefit from a lower salt intake.

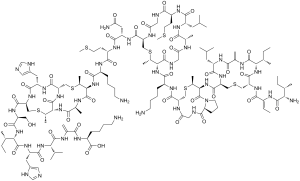

TG catalyzes the cross-link of side chains of two amino acids (glutamine and lysine) in liquefied proteins, and thus yielding ε- (γ-glutamyl)-lysine bond. This bond is stable against heat treatment or physical stress. Typically TG works within the protein of food materials, and contributes to improving texture properties. In case TG is used to combine quality meat/fish parts, TG works to the proteins which are added to the food applications. TG itself does not combine meat/fish parts. This is basically possible with TG and liquefied proteins. There is no technological function or effect of enzyme in the final product.